Install vapour control layer for pitched roof construction, and diffusible flat roof construction

Use CE Certified Airstop Timbertex membrane: diffusible, fixed Sd value 10m, approx. weight: 100gm/m2, EN 1849-2

- Install Airstop Timbertex vapour control layer mechanically to underside of rafters.

- 100mm overlaps are sealed, permanently airtight, with Airstop Elasto 60mm. single sided, high performance, stretchable and reinforced adhesive tape (meets (BS) EN-1206, (BS) EN1207).

- Perimeter substrates are primed using Isocell Uni Spray primer, self-adhesive, solvent-based, synthetic rubber primer

- Perimeters are sealed, permanently airtight Airstop Flex 75mm, single sided, high-performance split-liner (35mm/40mm) tape (meets (BS) EN-1206, (BS) EN1207), 35mm to vapour control layer, 40mm to substrate.

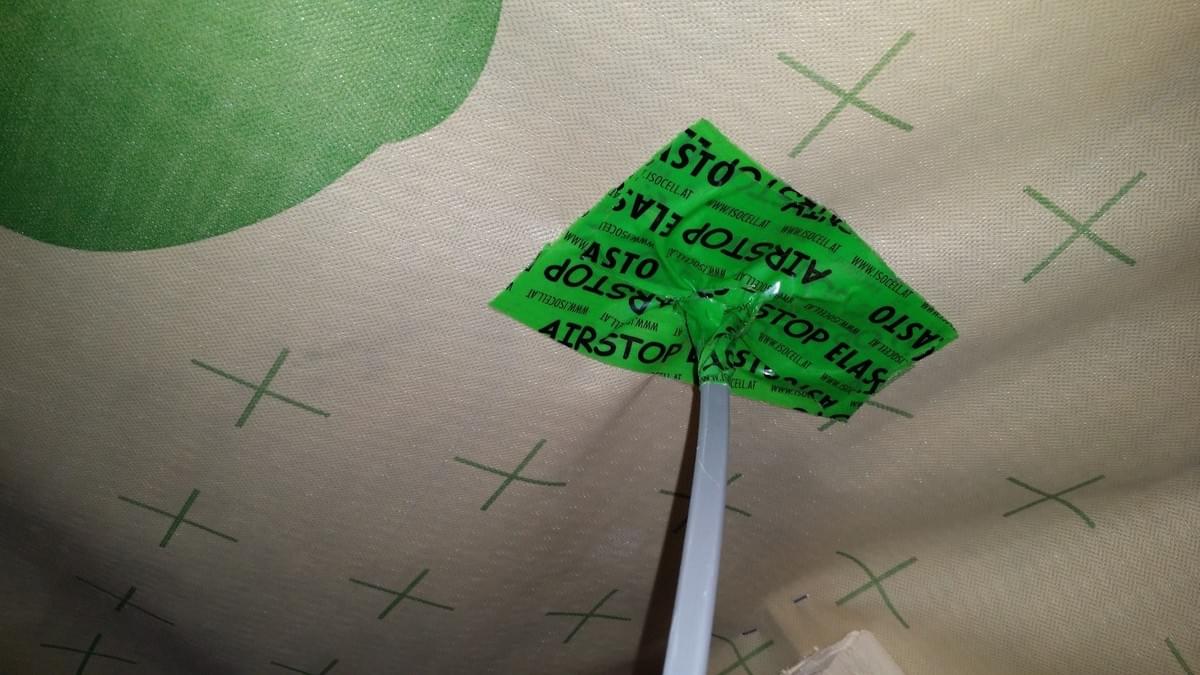

- Wire and pipe penetrations are sealed, permanently airtight, using Airstop Elasto 60mm. single sided, high performance, stretchable and reinforced adhesive tape (meets (BS) EN-1206, (BS) EN1207)

All products manufactured by: ISOCELL GMBH, BAHNHOFSTRASSE 36 - A-5202 NEUMARKT AM

WALLERSEE. Activities should be carried out in accordance with the manufacturer’s guidelines. See www.isocell.ie