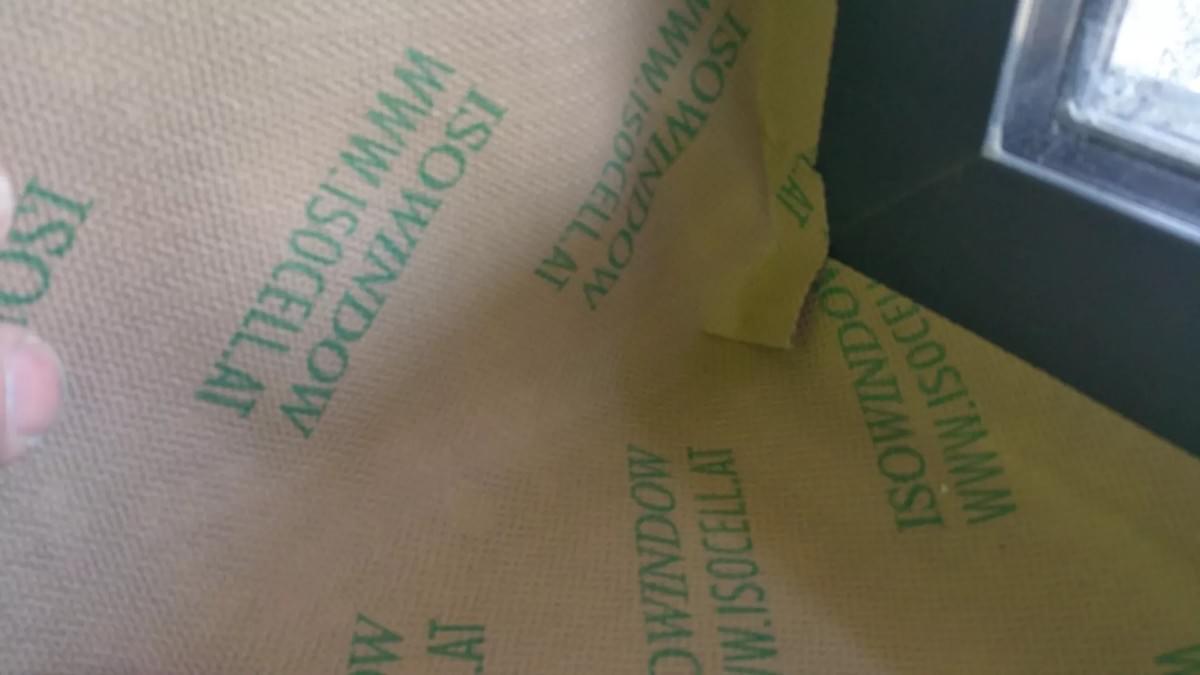

Seal Windows in a traditional cavity wall or solid wall Construction:

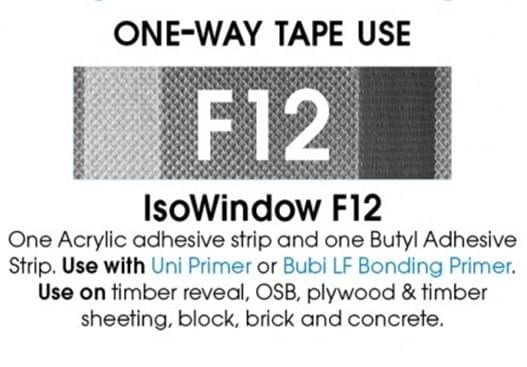

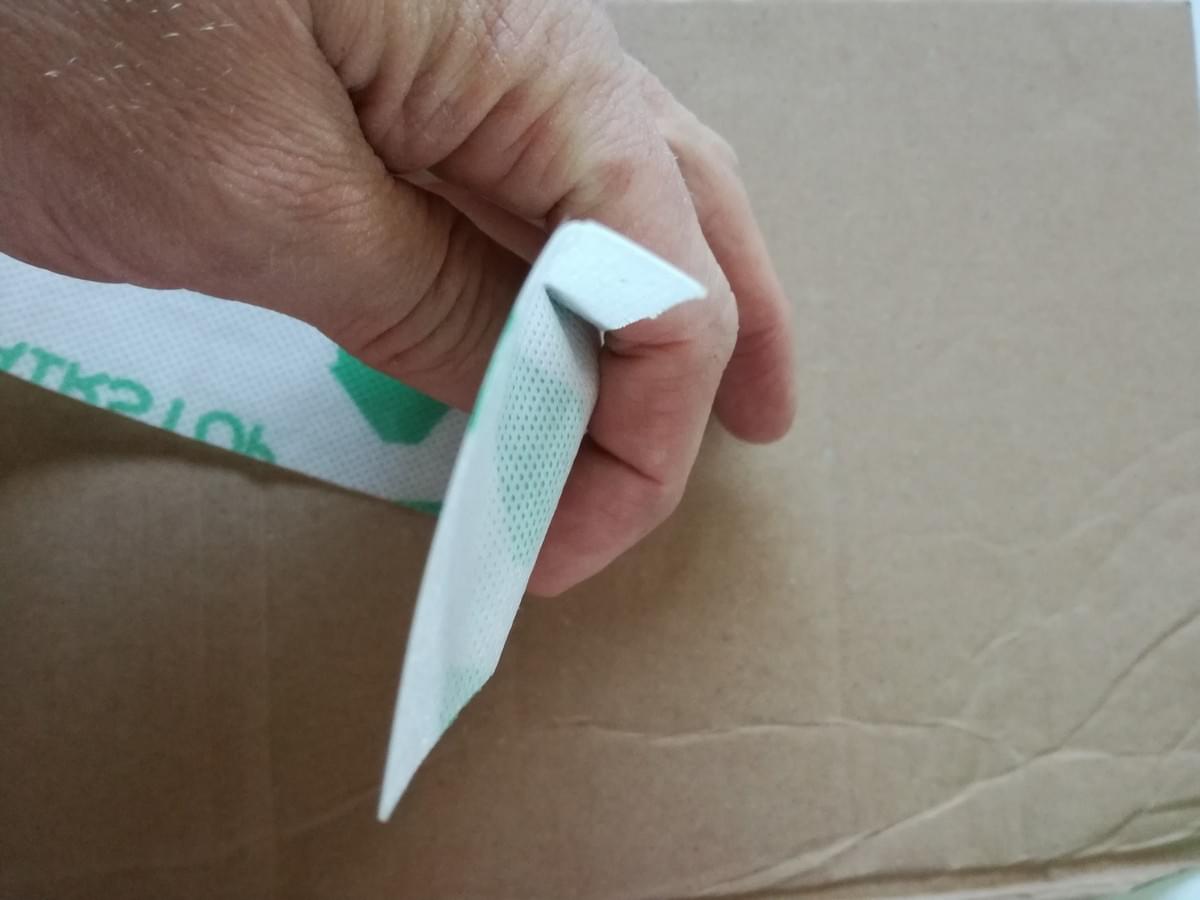

Use Isowindow F12, one way or two-way interior window tape, roll width “…………….mm,” heavy, high performance, fleece and alu backed airtight, diffusible, Sd value 40m tape, with incorporated acrylic adhesive strip and incorporated butyl strip (meets (BS) EN-1206, (BS) EN1207).

OR

Use Isowindow F1 one way or two-way interior window tape, roll width “…………….mm,” heavy, high performance, fleece and alu backed airtight, Sd value 40m tape, with an incorporated acrylic adhesive strip(meets (BS) EN-1206, (BS) EN1207), and A+ rated, Airstop Joint paste.

Seal Corners permanently airtight:

Use Airstop Flex 75mm single-sided, high-performance, split liner (35mm/40mm) tape (meets (BS) EN-1206, (BS) EN1207).

Solidify sanded and fibrous surfaces:

Prime substrate using Isocell Uni Spray primer, self-adhesive, solvent-based, synthetic rubber primer

OR

Prime substrate using Isocell Bubi, solvent-free, high-performance bonding primer.

All products manufactured by: ISOCELL GMBH BAHNHOFSTRASSE 36 - A-5202 NEUMARKT AM

WALLERSEE. Activities should be carried out in accordance with the manufacturer’s guidelines. See www.isocell.ie